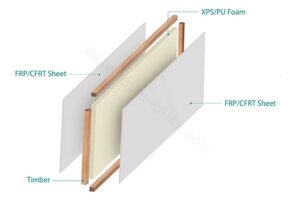

Side panels, front panels, top panels. Made of FRP/CFRT foam sandwich panels.

Refrigerated/Reefer Box Truck Body Manufacturer

Refrigerated/Rreezer Box Truck Body

Best Commercial Refrigerated/Freezer Truck Body Solution

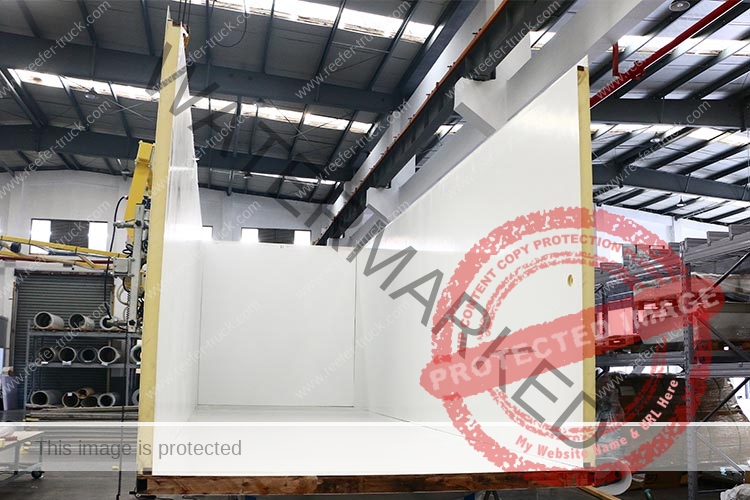

Carbody makes a full refrigerated/freezer truck body for 8-26 FT (2.5m-8m) trucks. It has excellent insulation. It uses FRP XPS sandwich panels, or CFRT refrigerated truck panels. They’re also called glass fibre reinforced plastic. It has a structural reinforcement design.

We have a design team that can customize it for you. Provide a variety of kit options.

A lightweight insulated truck box with great thermal insulation. It meets your needs, controls temperature, and is energy-efficient. It can transport frozen food, seafood, meat, vegetables, fruits, and dairy products. It can also carry catering. Carbody is the supplier of a high-performance refrigerated truck body.

- We offer body length from 3m~12m. 100% customised production. Easy to assemble

- 15 kinds of kit category options

- Good thermal insulation, waterproof, moisture proof, low cost

Extremely High Thermal Insulation Properties:

Light trucks are used for short-distance, refrigerated transport. They are also used for multiple loads and unloads. The temperature changes a lot during each loading and unloading. But, the refrigerated performance of the Light weight truck is no longer an issue!

Why Is The Cold Storage Performance So Excellent?

We use foam with a core, made of PU or XPS, for our car body. By increasing its density and thickness, it can insulate well. For high cold-storage needs, choose PU foam for its thermal insulation: 0.022W/mK. The other option is XPS, with 0.029W/mK, So, its thermal insulation is very good. XPS foam doesn’t absorb water, and it can keep the temperature. Our products have excellent thermal insulation. In hotter areas, they will satisfy you.

Advantage

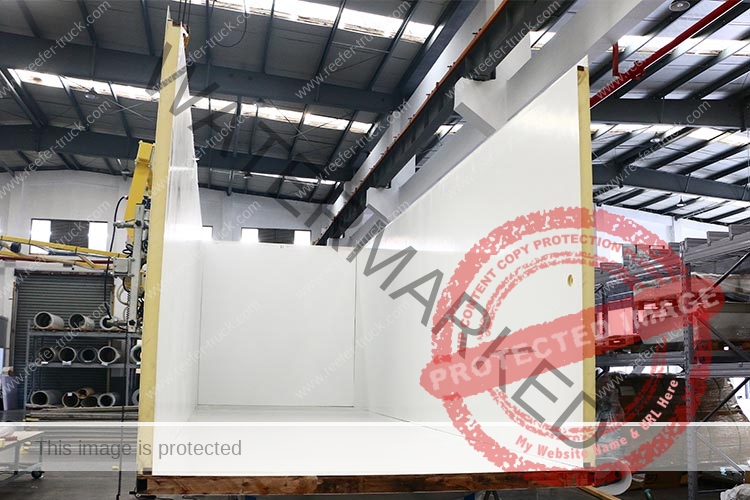

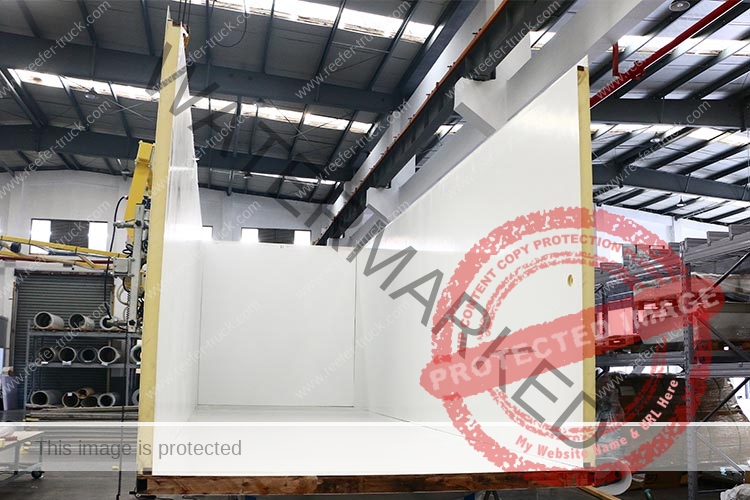

Carbody’s refrigerated truck bodies have 20 years of experience. They are for trailers, semi-trailers, and pickups. Our factory has world-class technology. We make stronger fibreglass insulated panels through continuous improvement. For longer truck bodies, we use a segmented skeleton or a layer of insulation. We innovate on various kits and win more and more customers’ trust and choice.

- Use lifespan long: With the help of our advanced fiberglass, the lifespan can be as long as ten years.

- Low cost: Costs less than an aluminum body.

- Rapid installation: We design and deliver with speed. This makes it easy to install; you can assemble a truck body in just 1 day. Save time and cost.

- Aesthetically pleasing: Our truck bodies are neat and smooth. They look good and are more exquisite.

- Not easy to corrode: We used advanced polymer plastic. It has a stable chemical structure, so it won’t corrode.

- High-strength material: Using FRP for the skin makes it durable in transport.

- Kit option: Customized kits option

- Resistant to extreme temperatures: It insulates well in the cold and in the desert.

Body Structure Performance:

We use high-strength insulation foam in our sandwich layer. Many customers offer widespread praise for it. And we have many kits to choose from.

Our high-end composite material for the truck bodies is strong and lightweight. It can reduce the weight of equipment. It is stronger than aluminum and much more affordable. We use it in 8-36 FT lightweight truck bodies. It cuts fuel costs by over 30% and boosts efficiency.

Carbody is the top maker of truck composite materials. We provide the best solutions for our customers.

Parameter

Comparison of different plastic and metal panels

| Attribute | FRP Panels | FRP+CFRT Panels | Galvanized Steel panels | Color Steel Sandwich Panel |

| Outer Material | FRP (Fiber Reinforced Plastic) | Outer: FRP Inner: CFRT (Continuous Fiber Reinforced Thermoplastic) | Galvanized Steel | Aluminum Alloy |

| Core Material | XPS (Extruded Polystyrene) or PU Foam | XPS or PU Foam | XPS or PU Foam | XPS or PU Foam |

| Advantages | 1. Aesthetic, suitable for high-demand appearance 2. Strong impact resistance, durable 3. UV-resistant, weatherproof 4. Repairable, long service life 5. Perfect match with XPS, PU foam core materials | 1. Strong impact resistance 2. Lower cost, economical and practical 3. CFRT lamination technology provides performance upgrades 4. Suitable for refrigerated trucks and large-scale applications | 1. Widely used in early applications, mature technology 2. Certain impact resistance | 1. Lightweight, rust-proof 2. Clean and aesthetic appearance 3. Lightweight, suitable for weight-sensitive applications |

Notes:

- Comprehensively comparing the above table, FRP + CFRT panels structure is by far the best choice for all businesses and individuals, both in terms of cost and performance.

- It supports customization in various sizes.

| Type | Length (m) | Width (m) | Height (m) |

| Light Weight Refrigerated Truck | 3.50 – 4.50 | 1.60 – 2.00 | 1.80 – 2.20 |

| Common lengths: 3.8 m, 4.15 m, 4.14 m, 4.12 m, 4.16 m, 4.17 m, 4.21 m, 4.25 m | |||

| All sizes can be customized | |||

Notes:

All sizes of light trucks can be customized. We can provide design drawings by the meter or foot.

Refrigerated Truck Kit

We offer you truck kits and truck floors with 100% compatibility. All kits are offered at the best prices.

Wall panels

Floors

The subfloor consists of FRP foam sandwich panels.

Made of 304 stainless steel, optional embedded E-Track.

Side door

Side door, rear door. Use high-strength materials to seal edges.

Edge and corner laps

Customized high-strength aluminum profiles.

Door frame

304 stainless steel door frame, using highly elastic rubber sealing strips.

Lock and hinge

Made of 304 stainless steel, optional hidden door lock design.

Multi-temperature zone partition

removable and tightly sealed multi-temperature zone partition. Multi-temperature zone refrigerated trucks can transport multiple goods in the same batch.

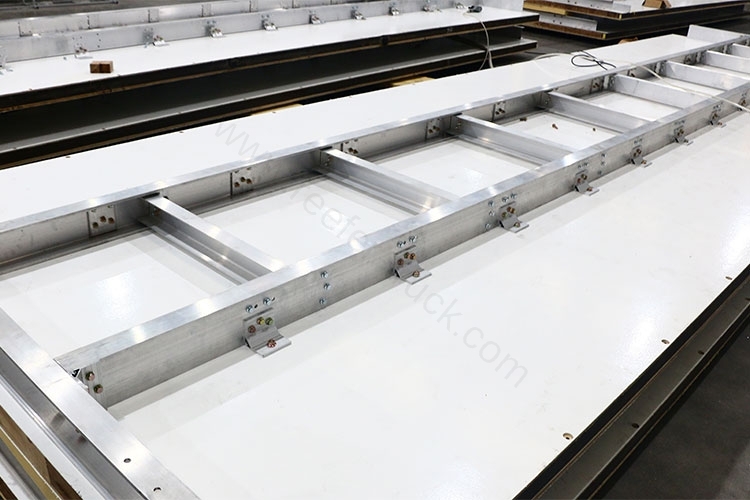

Subframe

Constructed from high-strength aluminum alloy, each component is connected with screws, and the spacing between the crossbeams is adjustable.

Refrigerated unit

Users can choose between independent and non-independent refrigeration units.

Rear bumper, side guardrails

made of high-strength aluminum alloy or carbon steel.

Meat hanging rail system

Constructed from 304 stainless steel, the setup allows for the addition of 3 to 4 rows of meat hooks.