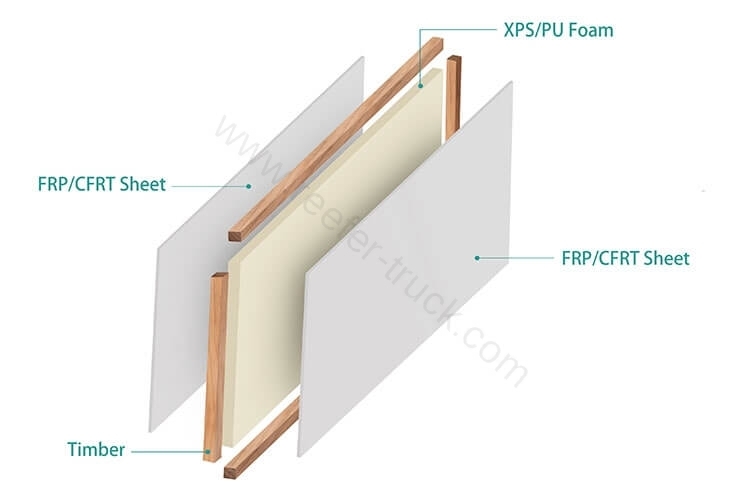

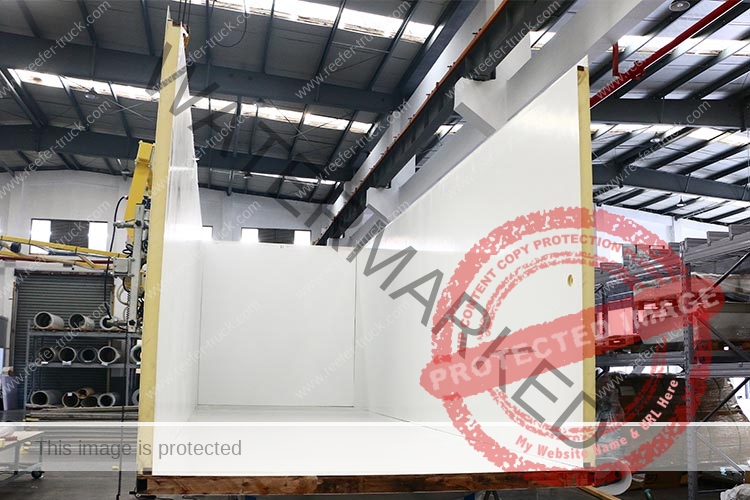

Side panels, front panels, top panels. Made of FRP/CFRT foam sandwich panels.

Insulated Box Truck Bodies Manufacturer

Insulated Truck Body FRP Panels

Best Insulated Truck Solutions

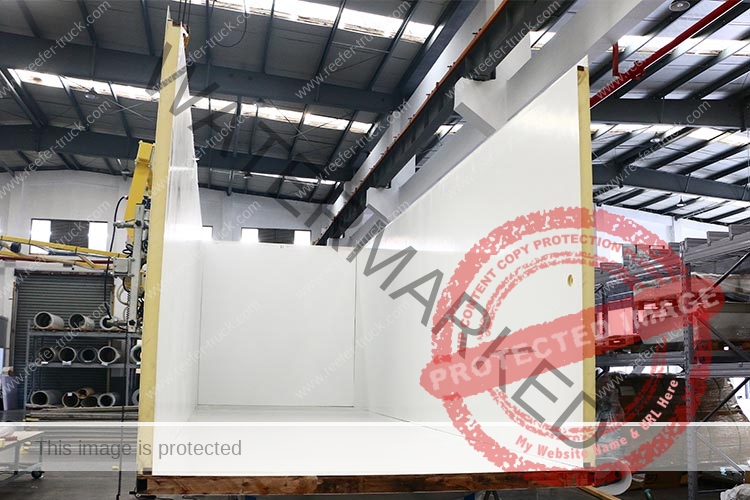

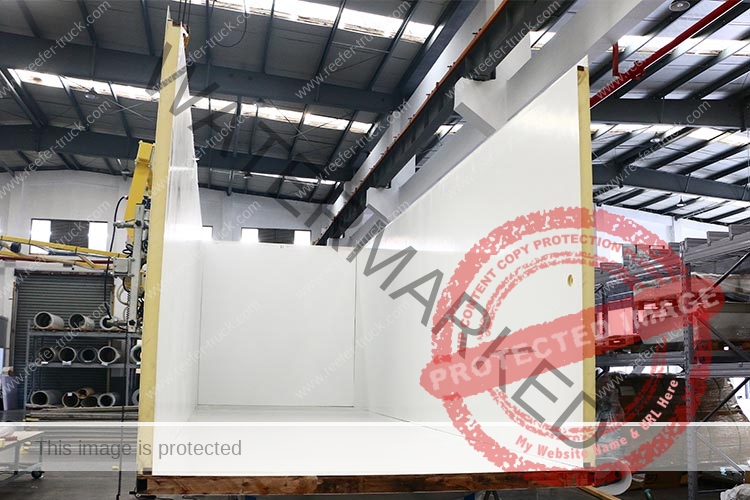

Carbody has been manufacturing insulated box truck bodies for over 20 years. They range in length from 3.2m to 12m. Insulated box truck bodies are also named “thermal truck bodies”. Are using modular panels. Manufacturers build insulated trucks with fiberglass panels and foam insulation. You can use them for lightweight trucks to heavy-duty trucks. Our insulated box trucks are popular for thermal transport. They can transport food, medicine, flowers, and industrial products.

- High quality FRP XPS/PU foam panels + waterproof design

- Full size customisation, kit option. CKD/SKD case delivery.

- Light weight design. Structural stability, high speed stability

Insulated Trucks FRP Panels Insulation Properties

Why FRP panels used in insulated trucks? Insulated box trucks use FRP panels. They are a composite material. It has two sides of FRP skin. The sandwich layer is XPS or PU foam, or ‘polyurethane’. Its low thermal conductivity makes it an excellent insulator. It is 0.018 to 0.028 W/(m-K) and has a density of 30-60 kg/m³. It is also very lightweight, unlike traditional aluminum panels and other foams. It can not only save fuel efficiency, but also make the internal temperature more stable.

Advantage

Our FRP insulated box truck can transport heat-sensitive food, chocolate, fruit, and vegetables. It’s insulated with FRP. Using XPS foam can insulate the heat well. Use a steel skeleton as the frame. You can customize it with rear doors, side panels, or double doors. It can combine with IoT tech to check temperature and humidity. Our high-quality products last a long time. They have earned us great market feedback. We have long-term customers in over 30 countries. Here are the advantages of choosing us:

- You can select polyurethane and XPS insulation materials according to the actual situation.

- Good insulation performance and advanced insulation design.

- You can customize the size and features for CKD case delivery. This will ensure easy installation.

- FRP skin, impact-resistant, with a tensile strength of up to 70-140 MPa.

- An insulated truck box has a long life of more than 10 years.

- FRP does not age or deform at -40°C to 70°C.

- Excellent corrosion resistance in harsh environments.

- XPS water absorption rate is less than 1%, and PU foam water absorption rate is less than 0.5%.

- Rapid production using high-precision CNC machines.

- High-quality glue is not easy to peel off or to deform.

- Can reduce fuel costs.

Body structure performance:

Insulated trucks use reinforced steel for the internal structure. It supports the body and improves impact resistance. Using FRP XPS foam panels can make designs lightweight and optimize weight. This can improve fuel efficiency. It won’t shake at high speeds. It’s more stable and safe. It has multi-layer waterproof protection. It uses super glue to ensure thermal insulation.

Parameter

Comparison of different plastic and metal panels

| Attribute | FRP Panels | FRP+CFRT Panels | Galvanized Steel panels | Color Steel Sandwich Panel |

| Outer Material | FRP (Fiber Reinforced Plastic) | Outer: FRP Inner: CFRT (Continuous Fiber Reinforced Thermoplastic) | Galvanized Steel | Aluminum Alloy |

| Core Material | XPS (Extruded Polystyrene) or PU Foam | XPS or PU Foam | XPS or PU Foam | XPS or PU Foam |

| Advantages | 1. Aesthetic, suitable for high-demand appearance 2. Strong impact resistance, durable 3. UV-resistant, weatherproof 4. Repairable, long service life 5. Perfect match with XPS, PU foam core materials | 1. Strong impact resistance 2. Lower cost, economical and practical 3. CFRT lamination technology provides performance upgrades 4. Suitable for refrigerated trucks and large-scale applications | 1. Widely used in early applications, mature technology 2. Certain impact resistance | 1. Lightweight, rust-proof 2. Clean and aesthetic appearance 3. Lightweight, suitable for weight-sensitive applications |

Notes:

- Comprehensively comparing the above table, FRP + CFRT panels structure is by far the best choice for all businesses and individuals, both in terms of cost and performance.

- It supports customization in various sizes.

| Type | Length (m) | Width (m) | Height (m) |

| Insulated | 3.50 – 9.60 | 1.60 – 2.20 | 1.80 – 2.20 |

| Common lengths: 3.50, 4.8m,5.6m,6.8m,9.6m | |||

| All sizes can be customized | |||

Notes:

All sizes of light trucks can be customized. We can provide design drawings by the meter or foot.

Kit

We offer you insulated truck kits and truck floors with 100% compatibility. All kits are offered at the best prices.

Wall panels

Floors

The subfloor consists of FRP foam sandwich panels.

Made of 304 stainless steel, optional embedded E-Track.

Side door

Side door, rear door. Use high-strength materials to seal edges.

Edge and corner laps

Customized high-strength aluminum profiles.

Door frame

304 stainless steel door frame, using highly elastic rubber sealing strips.

Lock and hinge

Made of 304 stainless steel, optional hidden door lock design.

Multi-temperature zone partition

removable and tightly sealed multi-temperature zone partition. Multi-temperature zone refrigerated trucks can transport multiple goods in the same batch.

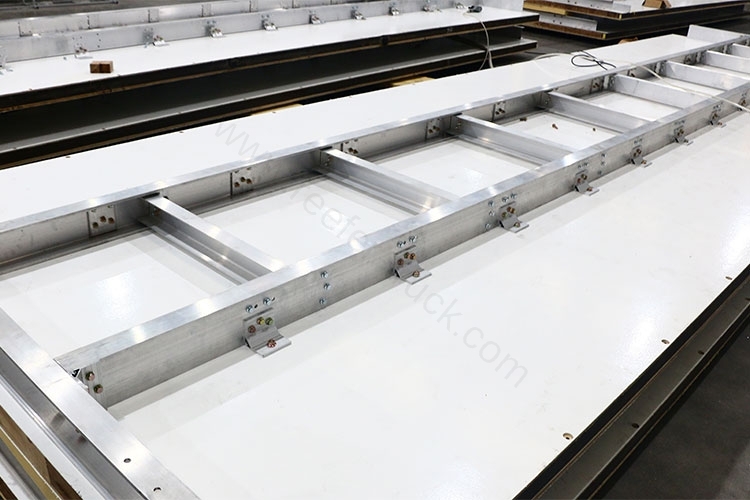

Subframe

Constructed from high-strength aluminum alloy, each component is connected with screws, and the spacing between the crossbeams is adjustable.

Refrigerated unit

Users can choose between independent and non-independent refrigeration units.

Rear bumper, side guardrails

made of high-strength aluminum alloy or carbon steel.

Meat hanging rail system

Constructed from 304 stainless steel, the setup allows for the addition of 3 to 4 rows of meat hooks.

Frequently Asked Questions

In refrigerated freezer trucks, PU foam insulates better than XPS foam. But, PU absorbs water. Its insulation weakens over time. XPS foam won’t absorb water. So according to the actual use, XPS foam is more recommended.

Insulated trucks using FRP panels are the best choice. FRP panels have a high-strength skin and a PU foam core. They insulate better, resist water, and last longer. Using FRP PU panels makes the body lighter. This improves fuel efficiency and cuts costs.

Insulated trucks can transport heat-sensitive products. They don’t need separate refrigeration equipment. They can cool and control the internal temperature with great efficiency. Insulated trucks are a type of cold chain transport.

They build them with FRP panels and polyurethane foam to prevent heat transfer. They can carry fresh fruit and vegetables, dairy products, meat, and other goods. It reduces the absorption of heat by these products. It protects the products from reaching their destination.

There are semi-trailers among the light trucks. But, they are smaller than driving and other large full trailers. Generally, a semi-trailer refers to the front of the car behind a trailer with a small carriage.

Carbody makes the truck’s main body from plastic foam panels. It uses FRP and CFRT foam panels as the primary materials in various kit compositions. The whole set of reefer body structures has high strength. It also has good heat insulation and excellent protection. CARBODY is a professional manufacturer of refrigerated bodies and their parts.