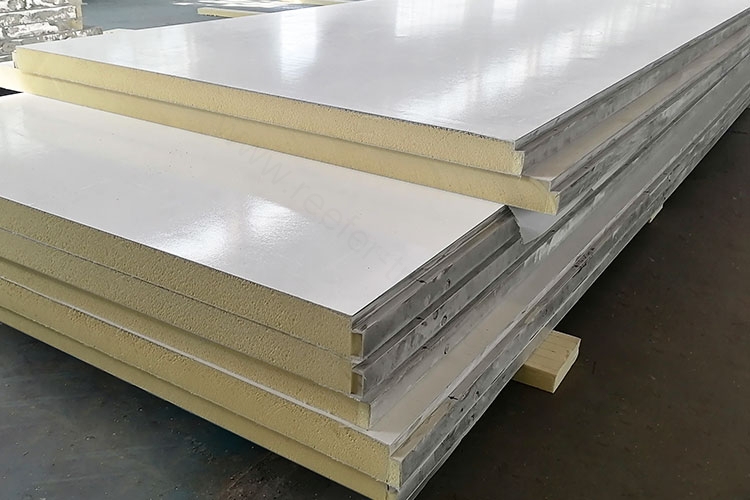

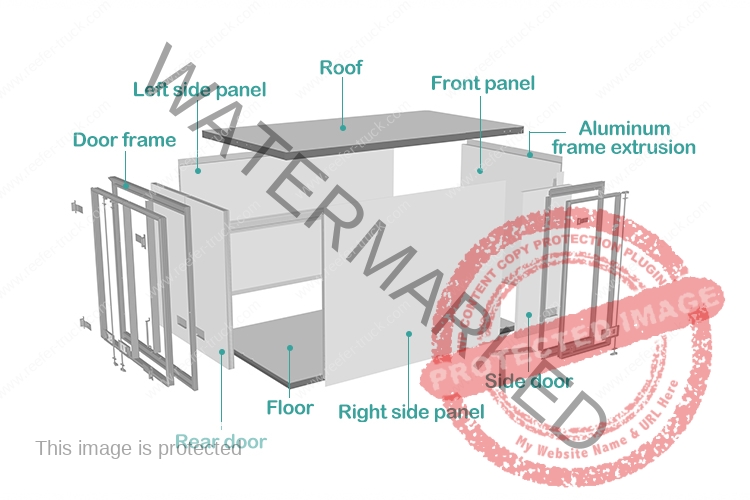

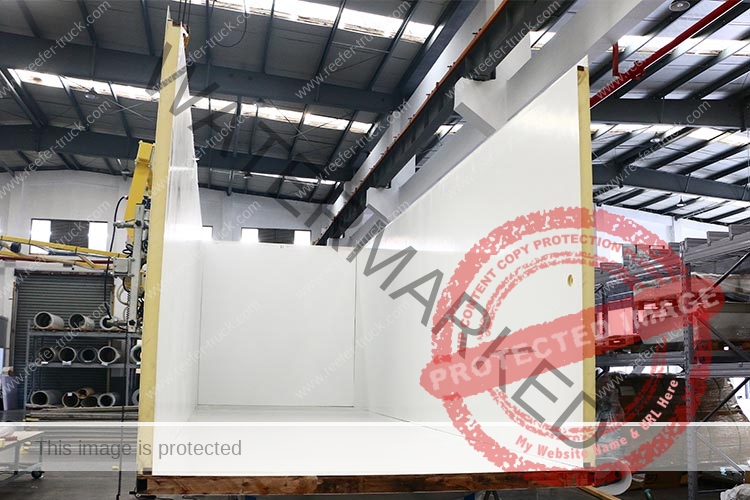

Carbody specializes in the production of refrigerated and frozen carriages and trailers. Use the most suitable high-performance sheets FRP and CFRT for the skin and PU foam or XPS foam for the core. Our best supplier of refrigerated car body solutions.

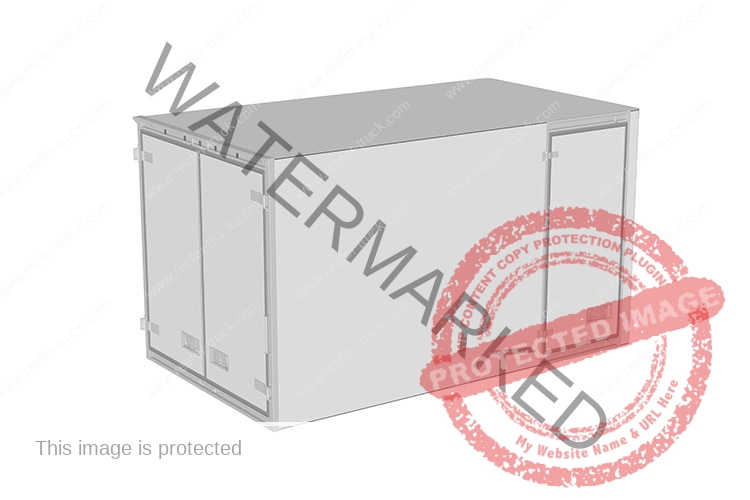

Our products suit semi-trailers, full trailers, lightweight box trucks, and small trailers. They should be 1.8 to 12 meters long.

We offer optional kits, 100% custom production, and CKD delivery. We are the best OEM/ODM manufacturer of reefer bodies.

- We offer 3-12 meter boxes for trucks.

- 100% support customized size and weight.

- Production lead time is 30 days, and fast factory response.