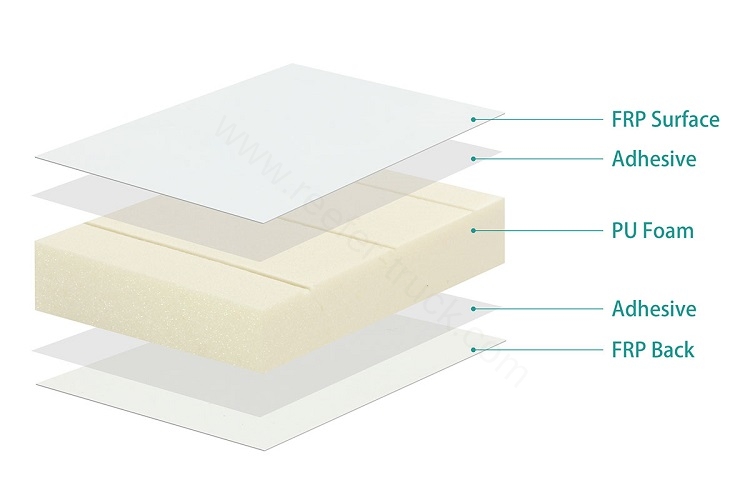

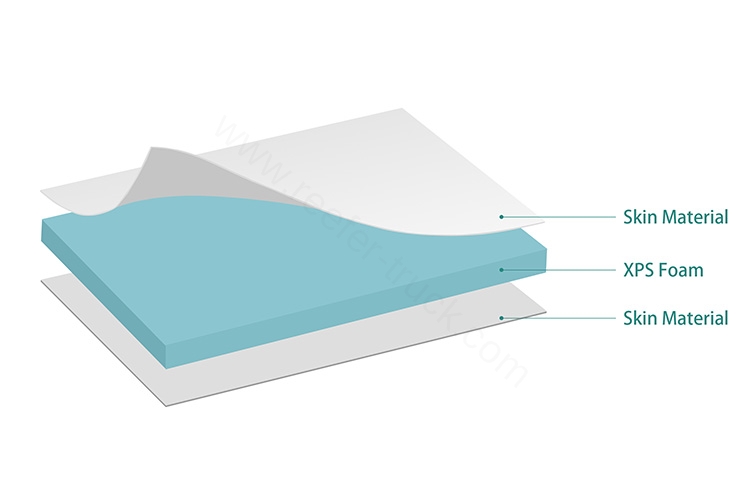

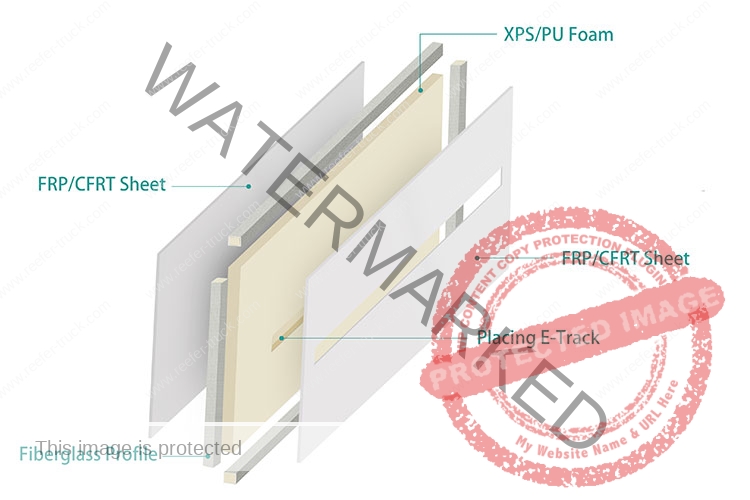

Wall panels for trucks and trailers can be installed on exterior walls, Side walls, and Roof, and are designed to be converted to reefer truck bodies, using composite material FRP foam panels, consisting of FRP skin on both sides, and the sandwich layer is XPS foam or PU foam.

It has the advantages of high strength and is not easy to scratch. With a special graphic layer, it can be protected from UV exposure for a long time, we can provide a full set of body customization, and CKD delivery, easy to install.

Application

Can be used for truck insulation panels, and truck wall panels. Generally used for semi-trailers, small refrigerated trailers, light weight truck refrigerated body panels, delivery trucks, heavy-duty vans, dry vans, and truck bodies of Exterior wall liner.