Fruit and Vegetable Refrigerated Truck Body Solution

We provide vegetable & fruit frozen truck body, this kind of food belongs to perishable food, in the transportation of fruits and vegetables, need a good environment and temperature, this kind of goods is very sensitive to the temperature requirements.

We provide FRP skin XPS foam panels, which can provide good insulation for fruits and vegetables, and we use high quality FRP panels with our self-developed insulation foam core. We provide professional solutions for the transportation and insulation of fruits and vegetables.

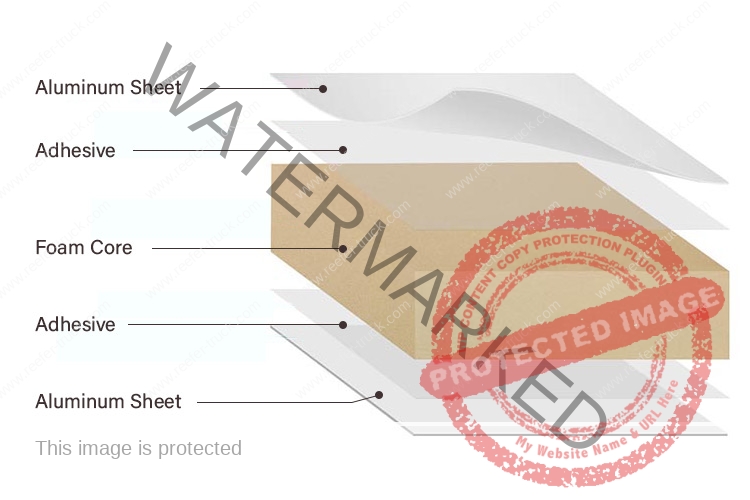

High-strength One-piece Composite Panels

Skin Selection: The outer skin is high-gloss FRP, which is smoother, close to a mirror surface. It’s more durable, and has a longer UV resistance time.

We choose New FRP as the inner skin , which has better impact resistance.

Core Material Selection: High density rigid PU foam, its thermal conductivity is extremely low and the thermal insulation effect is excellent.

Structural Reinforcements: Added nut plates to the connecting parts of our panels to make them stronger. And there are also high-strength screw connections to increase the strength of the truck body.

Long Service Life

·The internal truck cargo track is not protruding, which is more aesthetic. The internal air duct is hidden. And the skirting board is a customized pultruded profile, which is smoother and has better impact resistance.

·6061 high-strength aluminum alloy subframe, which has excellent support and shock absorption effects.

·Whether it is a rectangular duct floor, T-shaped duct floor or non-slip diamond floor, it has excellent strength and corrosion resistance. Our truck floor is easy to clean, not easy to oxidize, and low maintenance cost.

Our Advantages

With their rich experience and excellent technology, we are committed to creating unique and innovative truck body designs for you.

Professional Design Team

We have professionals who specialize in refrigerated truck technical fields. These include digital modeling, styling, overall layout, body, electrical appliances, interior and exterior decoration, finite element analysis, etc.

Advanced Production Factory

CARBODY has advanced high-precision fully automatic production machines. Our professional factory will maintain high-efficiency production at all times.

Customized Tracking Service

You can customize the size, temperature control, refrigeration system, internal layout, etc. of the refrigerated truck according to your own needs.

You don’t need to worry about language issues, our professional sales staff can achieve barrier-free communication with our customers.

Application of Vegetable Truck Box

- Edible Fungi 0~4℃

- Vegetables 0~5℃

- Eggs 2~5℃

- Fruit 0~5℃

Features of Vegetable Truck Box

Environmentally friendly

Carbody fully considers environmental protection factors and adopts environmentally friendly materials and technologies.

Lightweight

Carbody is committed to providing customers with lightweight solutions.

Cost Saving

Choose Carbody, we can save you 10-20% of the cost of manufacturing integrated refrigerated truck bodies.

Thermal Insulation

Carbody uses our materials to make excellent insulated refrigerated truck bodies for you.

Quick assembly

In the process of design and manufacture, Carbody has completed 85% of the installation for you, and the remaining 15% can be quickly completed by only a few people.

Customizable

At Carbody, we provide customized SKD/CKD services, in addition to design and material services, only willing to provide you with the best design and manufacturing solutions and products.

High strength

Carbody promises to use 100% quality raw materials, and our truck body panels will not age after 3-5 years of use.

Waterproof

The XPS/PU composite foam board used by Carbody has excellent waterproof performance, so you don’t have to worry about water seepage and water leakage in the refrigerated truck body.