Small car tows it. We are using FRP foam panels, easy to install, and suitable for the last 1 km delivery.

- Size: 2 metres to 5 metres

- Load capacity: 3175kg or more

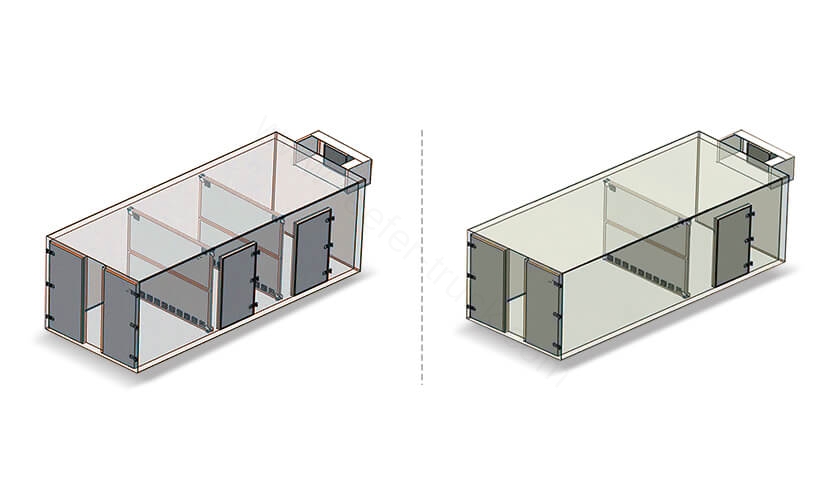

- Support multi-temperature zone

- Lightweight FRP XPS foam panels

We supply high-quality truck bodies for small, refrigerated trucks, pickups, semi-trailers, and medium-duty. They must have a capacity of 3-15 tons. Production length is 3-12 meters; common sizes are 3, 4, 6, 8, 9, and 10 meters, etc.; special loads and sizes can be customized.

Small car tows it. We are using FRP foam panels, easy to install, and suitable for the last 1 km delivery.

Lightweight Refrigerated Truck

A lightweight refrigerated truck body is ideal for quick installs. It has a CDK delivery, an FRP panel structure, and good insulation. There are many kit options.

Carbody makes all kinds of refrigerated truck bodies. We aim to adapt to the new era of refrigerated transport.

We also want to protect the environment and food safety. Using more eco-friendly, recyclable materials enhances the robustness of the truck body. We ensure the body is suitable for daily reuse. And, we maintain the insulation performance of the refrigerated truck body.

The truck body for cold chain transport can improve the cold chain supply chain. It works for both long-distance bulk transport and short-distance last-mile delivery.

Our advantages are fast installation, CKD delivery, and many kits. They helped us start our business and meet the rising demand for cold chain services. Make your business smoother.

Our truck bodies have many advantages:

Store goods in a suitable, refrigerated environment. Their temperature requirements vary. Our truck bodies have many temperature zones and compartments. You can keep goods warm, cold, and freezing at the same time.

For multi-temperature zones, click for more

Refrigeration and freezing differ in their temperatures and the goods they transport.

Companies use refrigerated transport for fresh vegetables, fruits, and dairy.

Companies use refrigerated trucks to transport meat, medicines, flowers, and so on.

For more on the difference between refrigeration and freezing, click to see more.

The refrigeratedtruck’s body has good thermal insulation and heat preservation properties. The use of FRP XPS foam panels as the main structure gives them good thermal insulation. They do not absorb water and have a 10-year lifespan. Their thickness is generally 50 mm, but it can be 100 mm. It depends on the use and the required refrigeration temperature.

The refrigeration system in refrigerated trucks can use two power sources. It can use the truck engine or a separate generator. It is important to choose a stable power source to make the cold chain more stable.

Refrigerated trucks use 0.5 to 1 gallon of fuel per hour. They also use 25% more fuel than dry trucks.

You can visit our factory anytime. You can see the manufacturing process, from design to finalizing materials and production. We will provide a precise estimate of the production time. We can arrange for a partner to help you track your project’s progress.

We design for you, free of charge. We aim to find the best solution for smooth installation and use on your truck. All you need to do is follow our parameters and we will provide you with the perfect design and drawings.