Fiberglass PET Foam Panels Manufacturer

Fiberglass PET Foam Panels

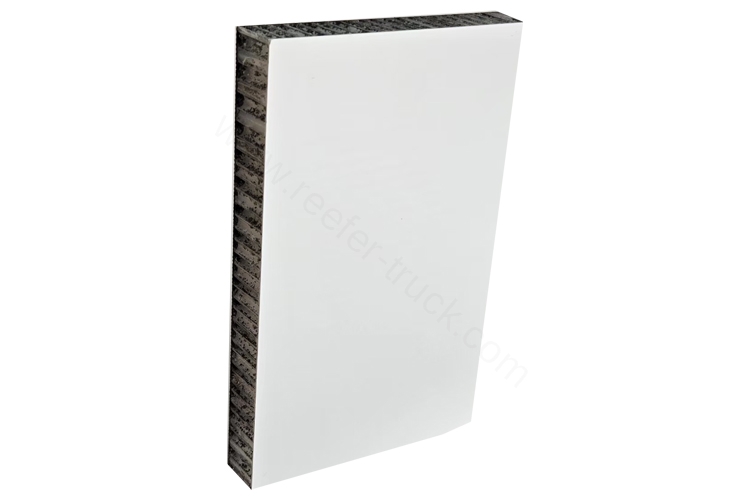

The fiberglass PET foam panels have an Fiberglass sheet exterior and a PET foam core. The process can also combine it with CFRT skin using a vacuum press.

PET is a popular lightweight material and is a high-performance material. You can generally use it for dry vans, boats, furniture, horse farms, mobile buildings, and more.

We offer OEM and ODM services. These include CNC machining, cutting, surface treatment, and custom packaging.

Advantages:

- Maximum support of 12 meters in length and 3.6 meters in width production

- Utilizes a leading vacuum compressor process

- Lowest cost in closed-cell rigid foam

Product Description:

Fiberglass PET foam panels are a common plastic composite. They are made of FRP and PET (polyethene terephthalate).

PET foam is a high-performance, lightweight material. It cuts costs and has excellent performance.

Fiberglass PET panels are closed-cell rigid foam. It does not absorb water, is strong, and is easy to cut. It replaces many materials as a filler core. It is recognized as a recyclable material. PET foam panels can be laminated with CFRT and FRP. It can also be laminated with steel, aluminium, plywood, and other materials.

Product Characteristics:

Fiberglass PET material has excellent performance. Here are the benefits of PET foam panels.

High Strength:Combined with gel-coated FRP skin, it can withstand great pressure.

Reduced Cost:PET foam is almost the lowest-cost closed cell material and is also cost-effective.

Recyclable:PET is an environmentally friendly material that can be recycled.

Corrosion Resistant:FRP PET foam panels have excellent corrosion resistance.

Not easy to deform.FRP is a high-performance skin and is not easily deformed by impact.

Applications:

Fiberglass PET panels are popular worldwide. They are used in the automotive industry, flooring, wall panels, and mobile homes. They contain:

- Dry van

- Flooring

- Wall panels

- Ceilings

- Aerospace

- Caravans

- Yachts and ships

Specification:

parameters

| Specification | Details |

|---|---|

| Skin | Fiberglass. Optional: CFRT |

| Core Material | PET Foam |

| Density | 50~300kg/m³ |

| Length | Up to 12 meters (12000mm) |

| Width | Up to 3.6 meters (3600mm) |

| Thickness | 3.0~120mm |

| Origin | Jiaxing, Zhejiang, China |

| Production Method | Custom Production |

| Trade Terms | FOB, CFR, CIF |

| Ports | Shanghai Port, Ningbo Port |

Standard

| Items | Unit | Value |

|---|---|---|

| Density | Kg/m3 | 50~300 |

| Compression Strength | Mpa | 8.5~5.20 |

| Compression Modulus | Mpa | 73~235 |

| Tensile Strength | Mpa | 1.4~4.0 |

| Tensile Modulus | Mpa | 90~275 |

| Shearing Strength | Mpa | 0.55~2.05 |

| Shearing Modulus | Mpa | 13.5~70.0 |

| Closed Cell Rate | % | ≥99 |

| Thermal Conductivity | W/m·K | 0.22~0.25 |

| Water Absorption | % | 0.1~0.3 |

| Operating Temperature | ℃ | ≤100℃ |