Carbody has a mature design and manufacturing team and promises to use 100% new raw materials. We are committed to providing customers with lower cost and better quality products. Here we will share a case of a dual-temperature zone refrigerated truck body from one of our customers for your reference.

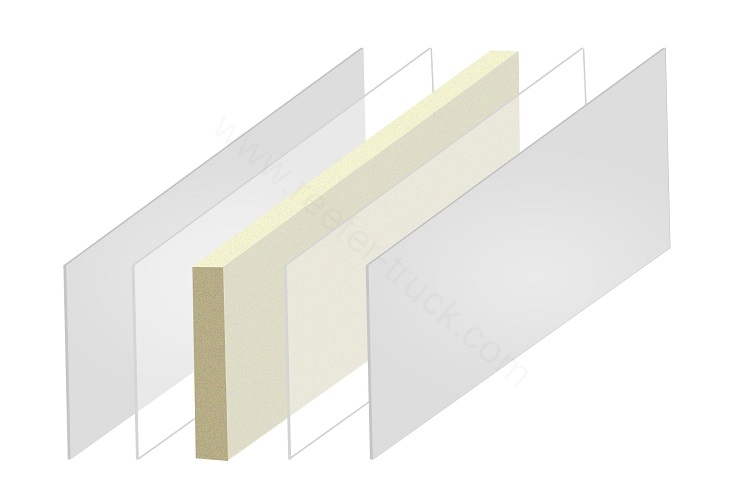

·Materials

For the outer skin, we chose smoother and more durable high-gloss FRP for our customer, which has longer UV resistance; for the inner skin, we chose CFRT, which is more impact-resistant.

Inside the trunk body, the truck e-tracks and air ducts are hidden design, and the skirting board is customized pultruded profile, which is flatter and at the same time, has better impact resistance.

The door frame surface is 304 stainless steel food grade, laser welded, no weld points or weld marks on the surface, and is high quality polished.

The entire interior of the truck body is made of stainless steel, aluminum alloy, and composite materials with no protrusions, making it easier for users to clean.

·Multi-temperature Zone Design

The truck box is designed with dual temperature zones. Hard partitions and slides can be used to control the temperature zone space, which is very convenient to use. Dual temperature zones have larger loading volume and are more impact resistant.

In addition, we also performed edge treatment on the dual-temperature zone partition to make sliding easier and sealing better. Composite reinforced beams and girders are stuffed with foam for better insulation. Broken bridge design, 5mm components prevent the heat transfer.

These result in a longer insulation time of the trunk and a more uniform temperature inside the truck body, which can be used for medical grades (medical refrigerated trucks have higher requirements for boards).

·Truck Body Details

Unlike other manufacturers, Carbody customized the curved design around the edges of the truck box for our customer instead of the traditional right angles, which greatly reduces wind resistance.

The panels are pre-embedded with automotive-grade positioning, and the side panels are pushed into place for easy installation and use, and the bonding is more beautiful.

The slide rails in the carriage adopt a hidden design, making cleaning more convenient.

·More Sincere Materials

Most of the raw materials used by other domestic refrigerated truck manufacturers to produce accessories are 2mm stainless steel (actual 1.8mm), but we use customized 2.2mm stainless steel for our customers.

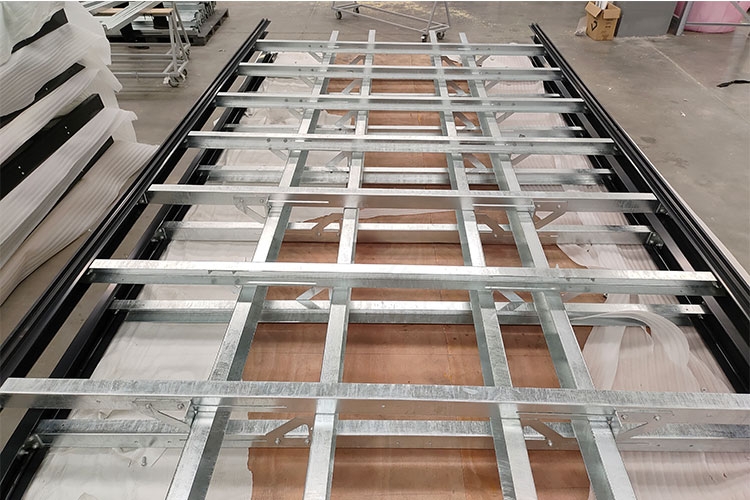

The body panels are connected with glue + reinforcement bolts, and the bolts use M10 bolts with stronger impact resistance.

The rear door frame of the truck body has no dents and no rivets. The thickness of the stainless steel used is 2.2mm, which is more solid and durable.

·Accessory

Broken Bridge Design We use composite materials to strengthen the beams, steel plates are added to the beams, and foam is added to the embedded pipes to prevent heat transfer.

Refrigerator Can be equipped with different coolers.

Side Door There are hidden reinforcing plates for higher strength.

Back Door Higher precision, quick box closing, labor saving, easier sliding, special design of the door panel, good opening and closing experience, and more sealing (reason: the sealing strip is different from that of its peers).

Lock Lever Hidden lock lever design, more beautiful.

Door Panel It is connected by bolts and reinforced with steel plates to prevent sagging and ensure the torsion resistance of the carriage.

Floor We use marine wood flooring for greater performance and lighter weight.

Subframe Adjustable, suitable for a variety of chassis, such as Fiat, Mercedes-Benz, etc.

If you also want to customize such a multi-temperature zone refrigerated truck box, please don’t hesitate to contact us!