Made in Carbody

> Carbody’s chocolate refrigerated box custom service is designed to meet your specific needs, ensuring that your chocolate products maintain the best quality during transportation.

> According to your needs, our team will provide a professional chocolate refrigerated truck body design scheme and provide you with detailed technical parameters and specifications. We will also ensure that the equipment and accessories used are of high quality and able to meet your special requirements for chocolate products.

> In addition to providing high-quality chocolate refrigerated truck boxes, we also provide thoughtful pre-sales and after-sales services. Our sales and technical teams will provide you with detailed consultation and answers at any time to ensure your satisfaction with our products.

Panel Materials of Chocolate Refrigerated Truck Body

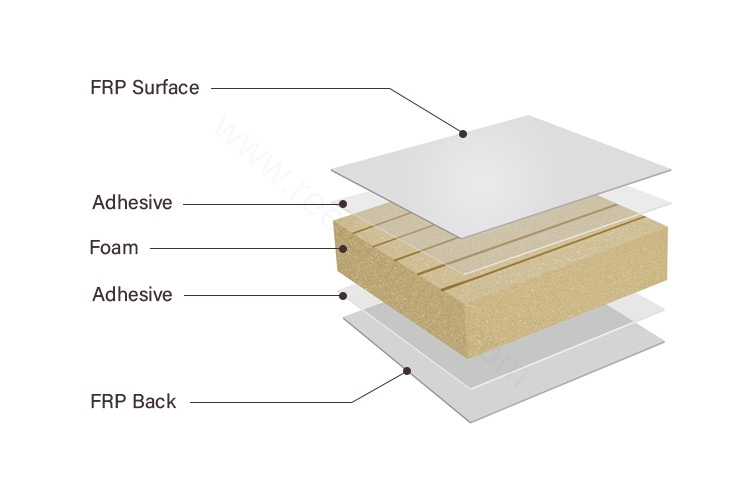

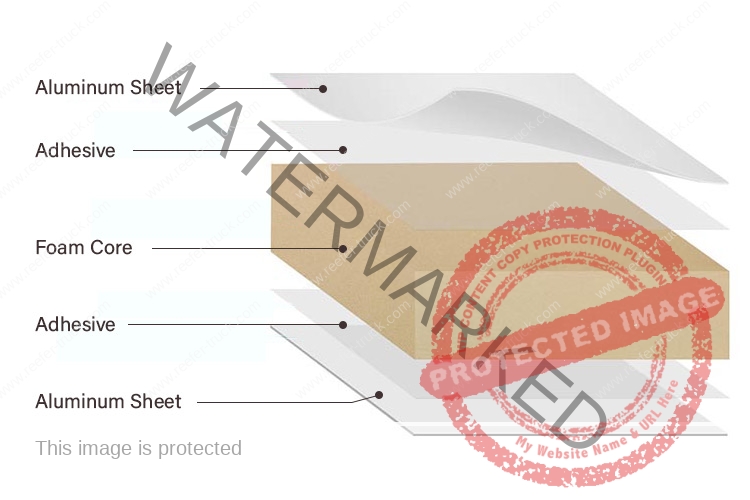

Usually this type consists of a series of insulating materials to isolate the outside temperature and environment. Commonly used insulation materials include PU, XPS foam core composite panels.

XPS (extruded polystyrene), is made of polystyrene resin as raw material plus other auxiliary materials and polymers, while heating and injecting a catalyst, and then extruded to form a rigid foam plastic board. lt has a very low Hygroscopicity (almost no water absorption), low thermal conductivity, and high compression resistance. lts surface is uniform and flat, and the interior is a completely closed cell, so it has the characteristics of high-pressure resistance, lightweight, non-absorbent,airtight, wear-resistant, and non-degradable.

PU Polyurethane rigid foam is a new closed-cell structure synthetic material with thermal insulation and waterproof functions. lts thermal conductivity is only 0.022-0.033W/(m*K), which is equivalent to half of the extruded board and has the lowest thermal conductivity among all thermal insulation materials.

Chocolate Refrigerated Truck Body Customized Service

Designed and manufactured in specialized factories

Carbody has modern facilities, with a total area of more than 10,000 square meters and dozens of professional workers to manufacture your truck bodies.

The Strength of Our Truck Body Design Team

Carbody has a professional truck body design team. With their rich experience and excellent technology, we are committed to creating unique and innovative truck body designs for you.

Customized For Chocolate Refrigeration

At Carbody, you can customize the size, temperature control, refrigeration system, internal layout, etc. of the chocolate refrigerated truck body according to your own needs.

Features of Our Products

Environmental Friendly

Carbody fully considers environmental protection factors and adopts environmentally friendly materials and technologies.

Lightweight

Carbody is committed to providing customers with lightweight solutions.

Cost Saving

Choose Carbody, we can save you 10-20% of the cost of manufacturing integrated refrigerated truck bodies.

Thermal Insulatio

Carbody uses our materials to make excellent insulated refrigerated truck bodies for you.

Thermal Insulation

In the process of design and manufacture, Carbody has completed 85% of the installation for you, and the remaining 15% can be quickly completed by only a few people.

Customizable

At Carbody, we provide customized SKD/CKD services, in addition to design and material services, only willing to provide you with the best design and manufacturing solutions and products.

High Strength

Carbody promises to use 100% quality raw materials, and our truck body panels will not age after 3-5 years of use.

Water Proof

The XPS/PU composite foam board used by Carbody has excellent waterproof performance, so you don’t have to worry about water seepage and water leakage in the refrigerated truck body.

Essential Product Details

| Model | Carbody ChocolateBox1.0 |

| Box Dimension(L*W*H) | Customizable |

| Operating Temperature | -15℃ to 0℃ |

| Box Material | FRP Skin PU Foam Core Sandwich Panel, Aluminum Skin Foam Composite Panel, Stainless Steel Skin Foam Composite Panel, Prepainted Steel Skin Foam Composite Panel |

| Load Capacity | 1.5T~35T |

| Supply Ability | 1000 Sets/Per Month |

| Supply Parts | Body Panels, Door Panels, Floors, Lights, Chassis, Bumper, Etc. |

| Delivery Time | 10-25 Days |

| MOQ | 10 Sets |

Packaging & Delivery

| Quantity(sets) | 1 – 50 | 51 – 100 | 101 – 200 | >200 |

| Lead Time (days) | 10 | 15 | 20 | To Be Negotiated |

Our Extensive Global Customers

Our customers are located in every corner of the world. We are customer-centric and constantly improve our services and product quality to meet the changing needs of customers. Whether it is to provide unrivaled products or provide refined solutions, we can fully meet customer requirements. We are grateful to our vast number of customers, your trust and support are the driving force for our development and growth.