Choosing a Refrigerated Truck Body can be difficult. Nowadays, the movement of refrigerated goods between different regions is increasing, and so is the need for Refrigerated Truck Bodies: they need to be able to meet the timeliness and freshness of the goods to be transported.

It is not only food and perishable goods that require refrigeration in the market, but also the medical sector, which is increasingly using cold chain services. We need good enough refrigerated truck bodies and kits to ensure that the required temperature is maintained during transportation and that energy consumption is reduced and efficiency increased.

What types of Refrigerated Truck Bodies are available?

There are different types of refrigerated truck bodies that can be used to maintain and control different temperatures and to meet the needs of different types of cargo. We need to choose the right refrigerated truck based on the actual cargo to be transported. This must have a certain understanding of the model, otherwise, it is easy to cause a lot of losses. Here are four main Refrigerated Truck Body types currently on the market.

Insulated truck body

Insulated trucks are not too high in refrigeration, they just need to insulate the outside from high temperatures and keep the inside of the truck as cold as possible. It has no refrigeration system, which saves more energy. Generally speaking, the insulated truck body can keep the temperature of 10-20℃, which is more used for food transportation.

For the insulated trunks, we recommend FRP skin XPS foam sandwich panels, which bring good thermal insulation properties.

Chiller Conversion Van

This type of chiller conversion van can be used for the transportation of non-sub-zero goods, some perishable products, such as flowers from florists non-frozen food, etc. Chiller Conversion Van is a van with access to refrigeration, which is generally better insulated than insulated vans. They will use thicker foam sandwich panels for the body box panels. The inside of the body will have a refrigeration unit to bring in a constant stream of cool air, and the box panels will also insulate the truck body from outside heat.

Semi-Refrigerated Truck Boxes

The heat insulation performance of semi refrigerated trucks is very excellent. Its box panels are typically made with either XPS or PU foam cores, but XPS foam cores are used more than 80% of the time. Another benefit of using these foams is that they do not absorb water.

Semi-refrigerated trucks can generally be used to transport food and other goods that require refrigeration. Since the operating temperature of a semi-refrigerated van is below 0°C, its refrigeration capacity and insulation are superior to that of an insulated van and chiller conversion van.

Fully refrigerated van box

The working temperature of a fully refrigerated van is very low. Not only does the box need to have enough cold air delivery, but it also needs to be well insulated. Even the doors and side panels are very thick. Only if the panels are very heat-resistant, can the trunk maintain excellent insulation performance through the transportation process. The thickness of the panels of a fully refrigerated truck like this one is at least 75mm. Full freezer trucks are generally used in long-distance transportation, such as transporting meat, beef, lamb, pork, chicken, duck, and so on.

Such refrigerated trucks usually use FRP skin XPS foam sandwich panels as the panels to maintain the low-temperature environment for a long period during transportation.

Multi-temperature refrigerated truck box

The structure of multi-temperature zone refrigerated truck boxes is different from the above types. It is divided into several temperature zones inside the box to meet the transportation needs of goods with different temperature requirements. Usually, it can be divided into room temperature zones, refrigerated zones, frozen zones, and so on. This type of truck is also the type that many cold-chain transportation companies will consider.

Need-to-know performance

Body structure:

There are very many body structures on the market today. They have different materials, different insulation properties, different life spans, and different strengths. According to the construction materials, there are iron carriages, aluminum alloy carriages, and composite panels carriages.

However, these are gradually eliminated.

In Europe, including Northern Europe, the box panels material is mainly FRP skin XPS foam panels. Most refrigerated trucks will use XPS foam panels, they have very good thermal insulation performance, and excellent pressure resistance, are waterproof, anti-scratch, and not easy to corrode.

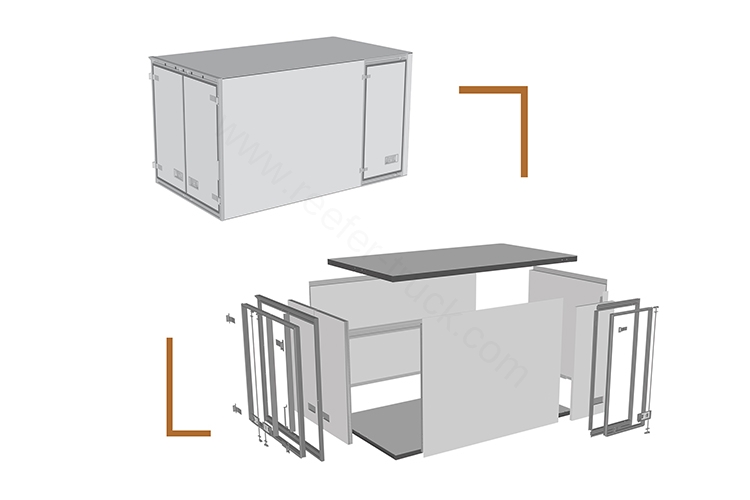

Boxes:

The insulation performance of refrigerated trucks is crucial, and the existence of gaps between the box panels can seriously affect its effectiveness. To minimize this possible hidden danger, we have developed the block type easy-to-put-together box panels and assembled them in CKD/SKD mode. These high-precision manufactured box panels ensure that the entire box is tightly fitted and firmly connected. In addition, it can save more labor and material resources for our customers.

Thermal insulation performance:

The insulation performance of a refrigerated truck determines whether the temperature inside the compartment is stable or not. Especially in the hot zone, the heat preservation performance is extra important. If the carriage does not have enough insulation performance, then the goods will be easily damaged.

Generally, XPS foam is preferred for the structure of the wagon, which has excellent thermal insulation properties, with a thermal conductivity of 0.024 W/m.K @ 10 degrees Celsius.

Kits selection:

The kits of the refrigerated body determine the functionality of the compartment and whether it will be used properly. Commonly used kits include rear door, side door, door frame, anti-skid aluminum floor, aluminum duct floors, subframe, multi-temperature partition, E-track, and so on.

Be sure to consider whether the manufacturer has these accessories and whether they are available as a package. The most important thing is to improve performance and save your installation time.

Refrigerated truck body life:

Generally speaking, the lifespan of a refrigerated truck body depends on the material used and the quality of the material.FRP material is a high-performance plastic, which can greatly enhance the structural strength of the truck body. Combined with the XPS foam, which is not easily corroded and does not absorb water, excellent thermal insulation can be achieved. Overall, a Refrigerated truck body can last for more than 10 years with only simple refrigerated truck daily maintenance.

Factors to consider

Budget

The overall construction cost of a refrigerated truck body is greater than that of a dry van body, and it is a type of vehicle that requires sufficient materials to meet the sealing requirements at the same time. When we look for suppliers, we must focus on price and choose the right manufacturer. For example, choose TOPOLO manufacturer’s reefer body. Not only is the price cheaper, but also supports quick assembly, it takes one person one day to assemble a box. The quality of the box is better than any other manufacturer, and the production efficiency is much faster.

Temperature requirements

You need to study and determine what temperature is required for the transportation of goods, and then select the corresponding type of compartment, as well as the material of the compartment structure and the required thickness. The refrigerated compartment must have enough refrigeration capacity to properly transport refrigerated goods.

Payload

Generally, we calculate the payload by the length, height, and width of the interior of the compartment. You can also calculate the payload by the amount of cargo loaded on the pallet. Choosing a large reefer container will allow you to carry more cargo.

Distance

You will also need to consider the distance of the shipment, which is usually city to city. For longer distances, consider choosing a reefer container with better insulation.