Meat Refrigerated Truck Body Made in Carbody

The meat refrigerated truck body is used to store meat and other perishable foods, usually used to transport pork, beef, mutton and other animal meat. This truck body has a special heat insulation and refrigeration system to keep the internal temperature within a suitable range. Thereby ensuring the freshness and safety of food. The vehicle’s refrigeration system can operate at different temperature settings, such as refrigerated (usually between 0°C and 4°C) or frozen (usually below -18°C).

The use of meat refrigerated trucks can not only improve the fresh-keeping time and quality of meat products, but also ensure safety and hygiene, and meet food hygiene standards. They are widely used in meat processing plants, supermarkets and catering industries to provide people with fresh and high-quality meat products.

Carbody’s meat refrigerated truck boxes are made of high-quality materials, with good thermal insulation performance and waterproof function, which can effectively isolate the temperature and humidity changes of the outside world. In addition, the truck bodies are also equipped with an adjustable temperature control system and electronic monitoring devices to monitor the temperature and humidity in the compartment in time.

Panel Materials of Meat Refrigerated Truck Body

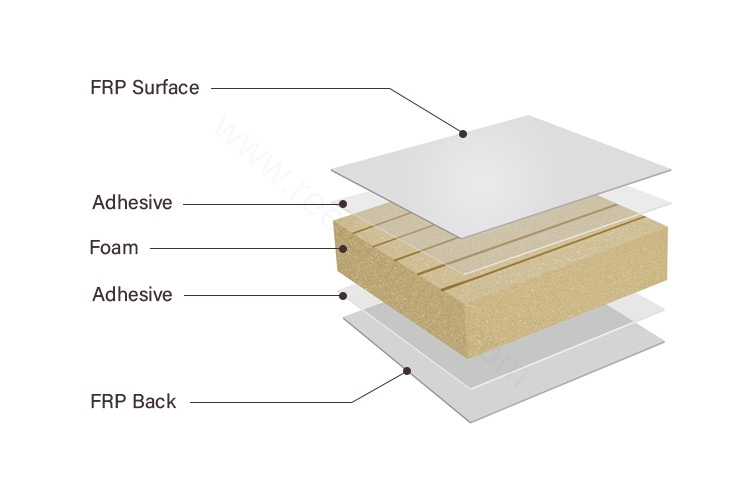

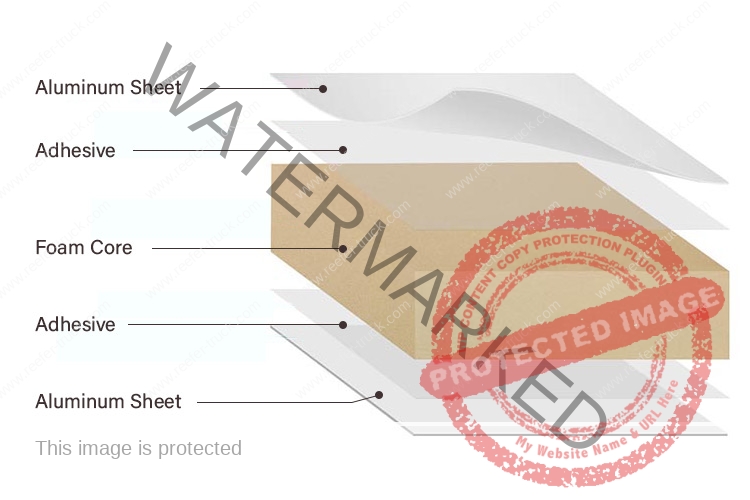

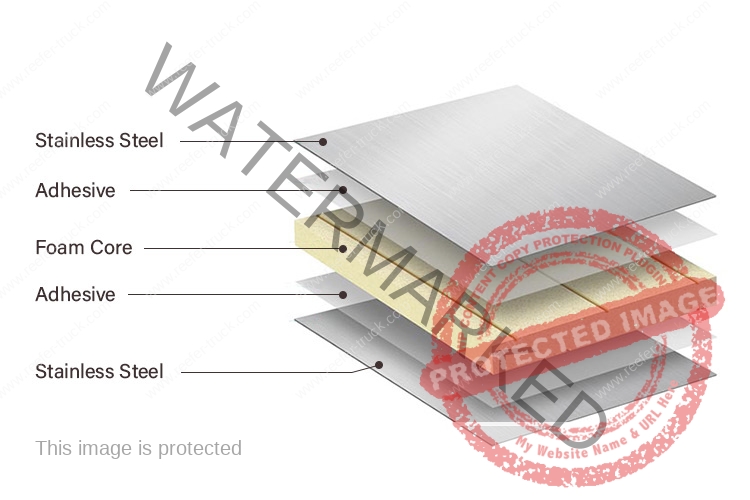

Usually this type consists of a series of insulating materials to isolate the outside temperature and environment. Commonly used insulation materials include PU, XPS foam core composite panels.

Fiberglass foam core panel is a new type of building material that uses glass fiber composite material as the panel, and is synthesized with foam core after high temperature heating. The selected fiberglass has the advantages of excellent corrosion resistance, anti-aging, and fire protection, while the foam core is characterized by light weight, sound insulation, and heat preservation.

Aluminum alloy has good anti-rust and anti-corrosion properties, long service life, and will not rust easily like color steel plates.

The foam core is light in weight and different types of foam cores have different functions: PU is heat insulation and fire protection; XPS is heat insulation and sound insulation.

The foam core aluzinc sandwich panel is a new type of composite material.The surface coating of aluzinc is aluminum-zinc alloy.The foam core material supplied by Carbody is high-quality closed-cell foam such as XPS,PU.

Our Unique Advantages

·One-piece truck body panel, easier to assemble.

·High-quality heat insulation materials, different from general heat insulation materials on the market, we use heat insulation materials with higher heat insulation efficiency and more stable performance.

·Truck body design service, a professional design team helps you solve various application problems.

·Various standard or non-standard accessories are available.

Features of Our Products

Environmental Friendly

Carbody fully considers environmental protection factors and adopts environmentally friendly materials and technologies.

Lightweight

Carbody is committed to providing customers with lightweight solutions.

Cost Saving

Choose Carbody, we can save you 10-20% of the cost of manufacturing integrated refrigerated truck bodies.

Thermal Insulation

Carbody uses our materials to make excellent insulated refrigerated truck bodies for you.

Fast Assmebling

In the process of design and manufacture, Carbody has completed 85% of the installation for you, and the remaining 15% can be quickly completed by only a few people.

Customizable

At Carbody, we provide customized SKD/CKD services, in addition to design and material services, only willing to provide you with the best design and manufacturing solutions and products.

High Strength

Carbody promises to use 100% quality raw materials, and our truck body panels will not age after 3-5 years of use.

Water Proof

The XPS/PU composite foam board used by Carbody has excellent waterproof performance, so you don’t have to worry about water seepage and water leakage in the refrigerated truck body.

Essential Product Details

| Model | Carbody MeatBox1.0 |

| Box Dimension(L*W*H) | Customizable |

| Operating Temperature | -15℃~0℃ |

| Box Material | FRP Skin PU Foam Core Sandwich Panel, Aluminum Skin Foam Composite Panel, Stainless Steel Skin Foam Composite Panel, Prepainted Steel Skin Foam Composite Panel |

| Load Capacity | 1.5T~35T |

| Supply Ability | 1000 Sets/Per Month |

| Supply Parts | Body Panels, Door Panels, Floors, Lights, Chassis, Bumper, Etc. |

| Delivery Time | 10-25 Days |

| MOQ | 10 Sets |

Packaging & Delivery

| Quantity(sets) | 1 – 50 | 51 – 100 | 101 – 200 |

| Lead Time (days) | 10 | 15 | 20 |

Our Extensive Global Customers

Our customers are located in every corner of the world. We are customer-centric and constantly improve our services and product quality to meet the changing needs of customers. Whether it is to provide unrivaled products or provide refined solutions, we can fully meet customer requirements. We are grateful to our vast number of customers, your trust and support are the driving force for our development and growth.