The insulated refrigerated truck body is made of high quality FRP (Fiber Reinforced Plastic) XPS/PU foam sandwich panels. This design combines the lightweight, high strength, corrosion resistance and aesthetic properties of FRP with the excellent thermal insulation and structural stability of XPS/PU foam, which brings a highly efficient, durable and reliable thermal insulation transportation solution for the cold chain logistics industry.

Description

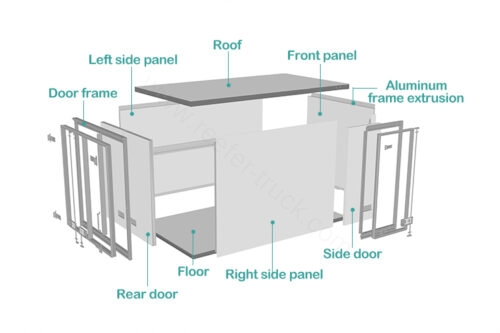

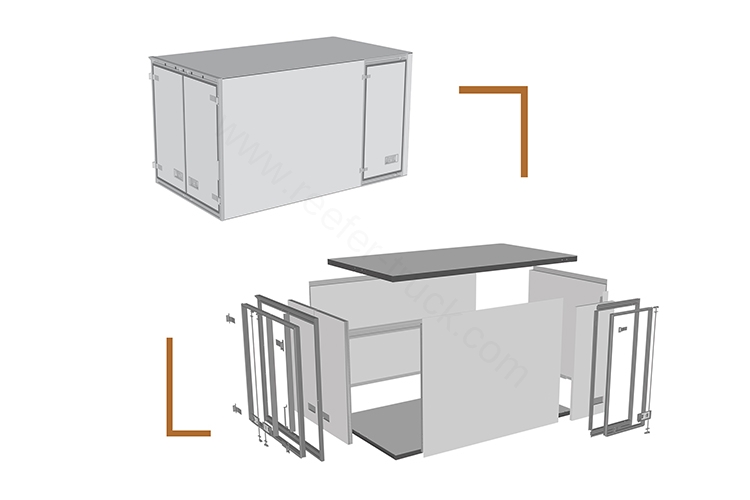

Structure Design

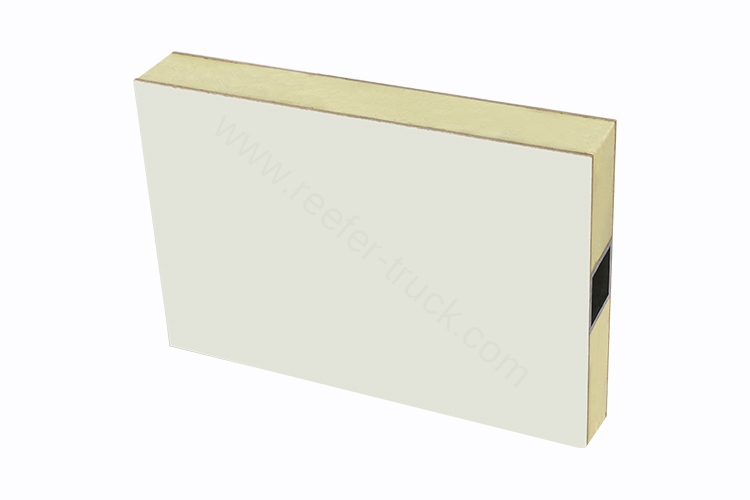

- One-piece composite panels: FRP panels usually adopt one-piece molding technology, with the middle layer of thermal insulation foam and the outer layer of weather-resistant food-grade FRP plate.

- Insulation layer design: The thickness of the thermal insulation panel is generally between 75-100 mm, which is adjusted according to the different requirements of the transported goods to ensure the best thermal insulation performance.

- Seamless connection: Seamless connection technology is used to prevent cold air leakage and improve insulation efficiency.

Body Materials

- Fiberglass Polystyrene Foam Sandwich Panel.

- Fiberglass Polyurethane Foam Sandwich Panel.

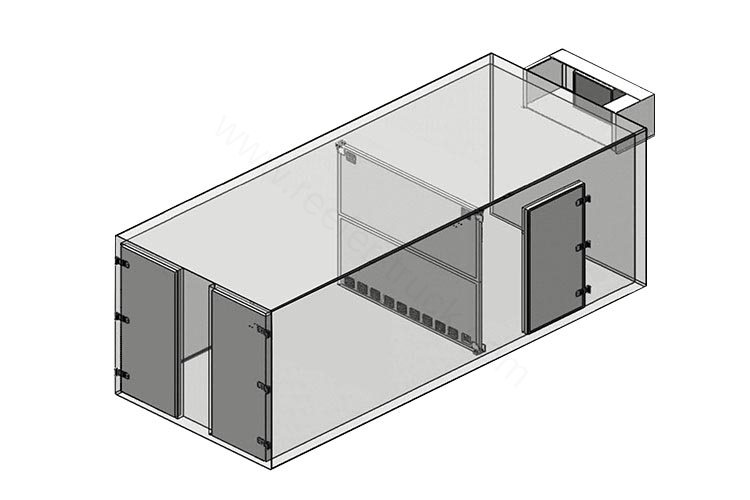

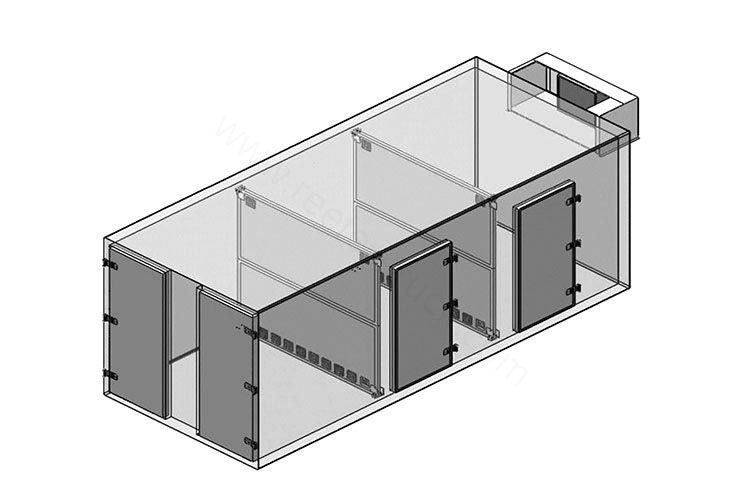

Refrigerated Truck CKD Kit Solution

Features

- Optimized design.

- Quick assembly.

- Thermal insulation.

- Durable.

- Waterproof and moisture-proof.

- Reduce manufacturing costs.

Application Scenario

- Fresh Food Transportation: including vegetables, fruits, meat and seafood, etc., to maintain freshness and taste.

- Pharmaceutical Cold Chain: ensure the safe transportation of sensitive pharmaceutical products such as vaccines and blood products in low temperature environments.

- Special Item Preservation: such as artworks, high-tech products, etc., which require strict temperature control.

Fast Assembly, Efficient Output

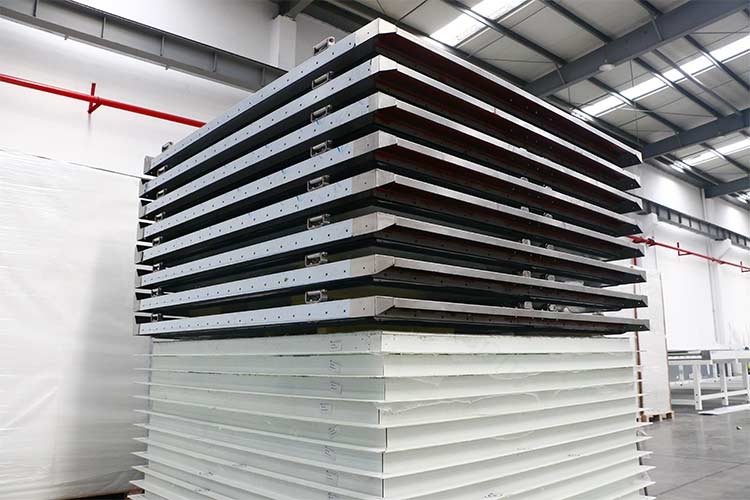

Fiberglass Sandwich Panel of Refrigerated Truck

We offer two high-performance insulation composite panel options: XPS (extruded polystyrene) insulation board and PU (polyurethane) foam sandwich panel, designed to meet the diverse needs of different application scenarios. Buyers can flexibly choose the appropriate density, thickness and other customized specifications according to specific project requirements to ensure the best insulation effect, structural strength and cost-effectiveness.

XPS Insulation Panels

- Thermal insulation.

- Not easy to deform.

- Lightweight.

- Waterproof.

- Durable.

PU Insulation Panels

- Lightweight.

- Low thermal conductivity.

- Corrosion resistant.

- Waterproof.

- Compression resistant.

- Flame retardant.

High-quality Thermal Insulation Materials & Advanced Production Technology

Our Refrigerated Truck CKD Kits

We focus on the unique needs of our customers and carefully design and manufacture a full range of refrigerated truck parts solutions. Here is an overview of some of the customized refrigerated truck body parts we can provide:

High-efficiency Refrigeration unit

Customized selection ensures that the goods maintain the optimal storage temperature during transportation.

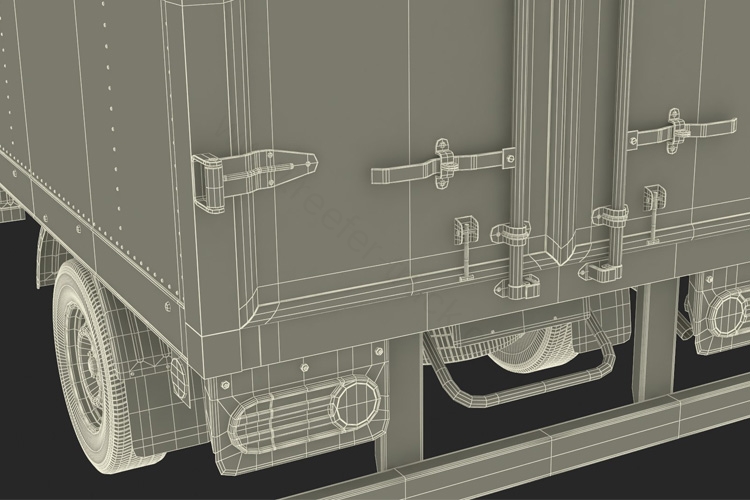

E-track Fixing System

Flexibly install various types of shelves and fixing devices to improve loading efficiency.

Rear Door Lifting Platform

Automated design simplifies loading and unloading process and improves work efficiency.

Advanced Door Lock System

Safe and reliable, easy to operate, and effectively protects the safety of goods.

Exquisite Corner Covers and Edging Profiles

Improve the appearance of the vehicle and enhance the stability of the body structure.

High-Brightness Safety Lights and Bumpers

Improve driving safety at night and in bad weather.

Optimize Subframe

Ensure smooth driving of the vehicle and extend its service life.

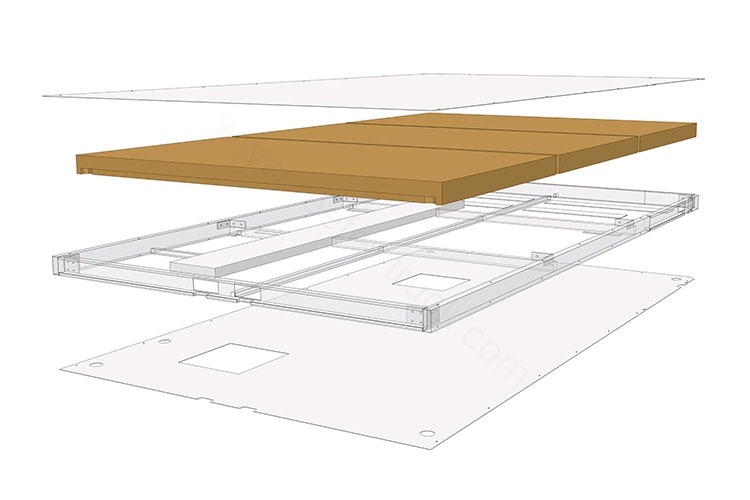

Laminated Floor Structure

Strong load-bearing capacity, non-slip and wear-resistant, easy to clean and maintain.

Suspension System

The structure is stable and can bear a large weight.Block, Modular, Quick Assembly

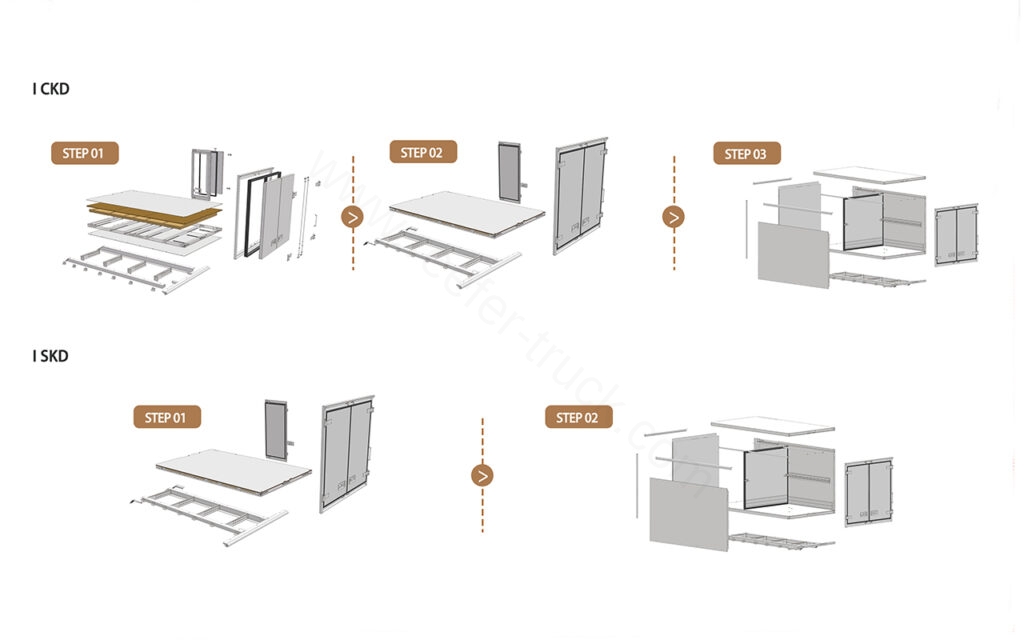

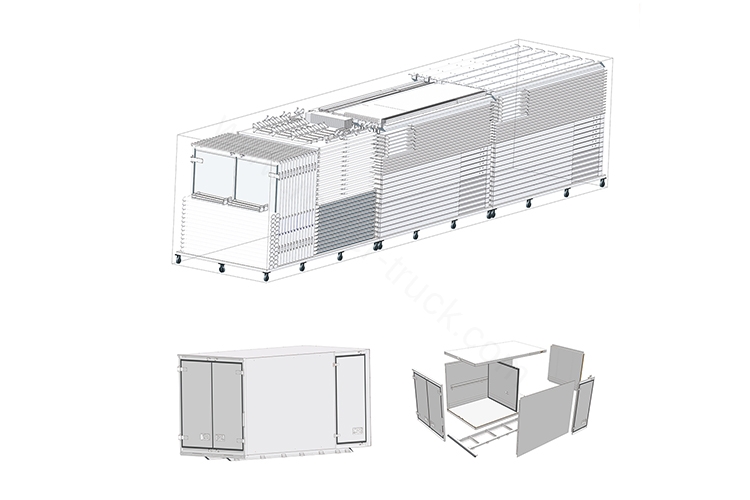

- Refrigerated truck CKD kits one-piece panels

- Quickly assembled with simple tools such as screws, glue, and screw guns

- 4 people + 2 hours = 1 box

- More efficient compared with traditional welding technology, which can save labor and time costs

CKD/SKD Service

Our CKD/SKD is very easy to assemble:

Packaging Solutions

Company Strength

With 20 years of experience in truck design and development, we have a team of more than 100 professional manufacturing elites who continuously promote product optimization and upgrading with superb skills and innovative thinking.

In order to serve global customers, we are equipped with an international service team composed of multilingual experts, proficient in more than 10 languages including English, Russian, French, Spanish, Portuguese, Arabic, German, Italian, Japanese and Korean, ensuring unbounded communication and considerate service.

So far, we have successfully established long-term and stable cooperative relationships with customers in more than 50 countries and regions around the world. This is not only a recognition of our product quality and design capabilities, but also a source of motivation for us to keep moving forward.