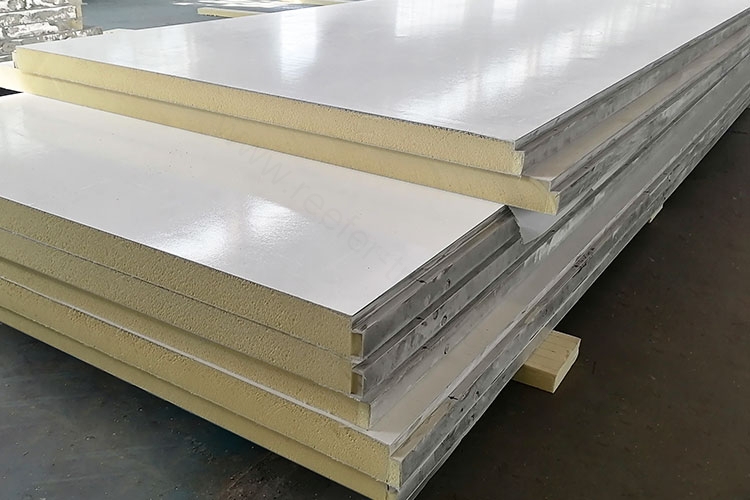

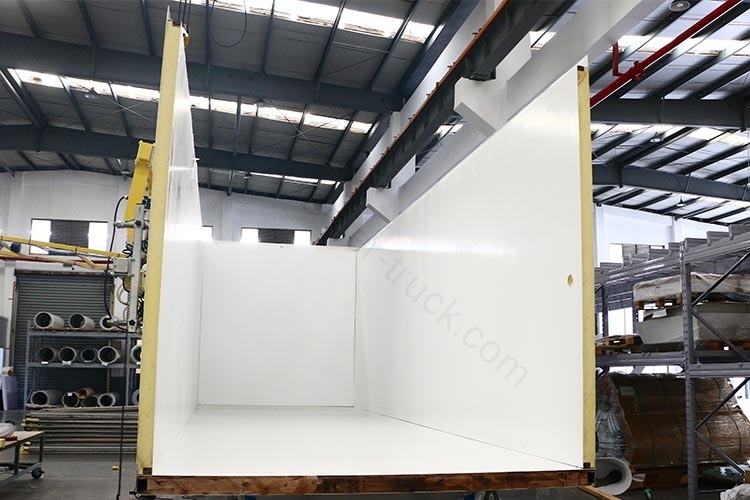

FRP PU/XPS foam sandwich panels are used for refrigerated trucks or freezer trucks, and FRP box bodies can get better insulation and heat preservation. The insulation of the foam can transport the goods better, its lightness can reduce the total weight, more saving, environmental protection, green.FRP foam panels can replace aluminum panels, or galvanized steel panels. Longer service life. We provide DIY and CKD case delivery.

We offer floor, side panels, rear panels (rear panels), front panels, and complete kit options.

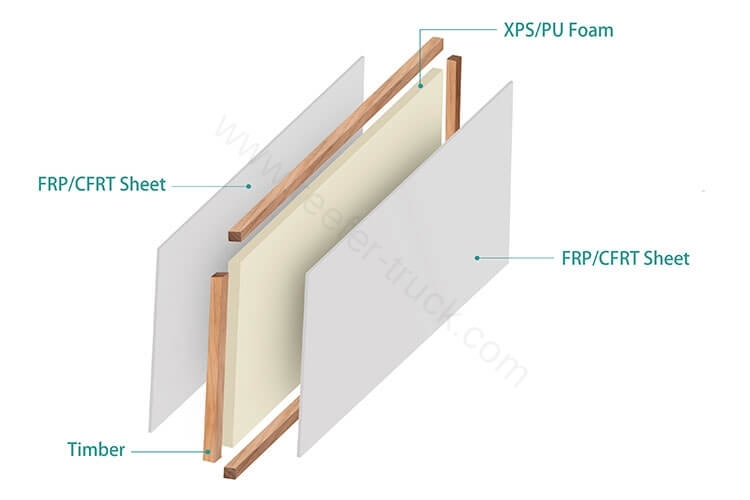

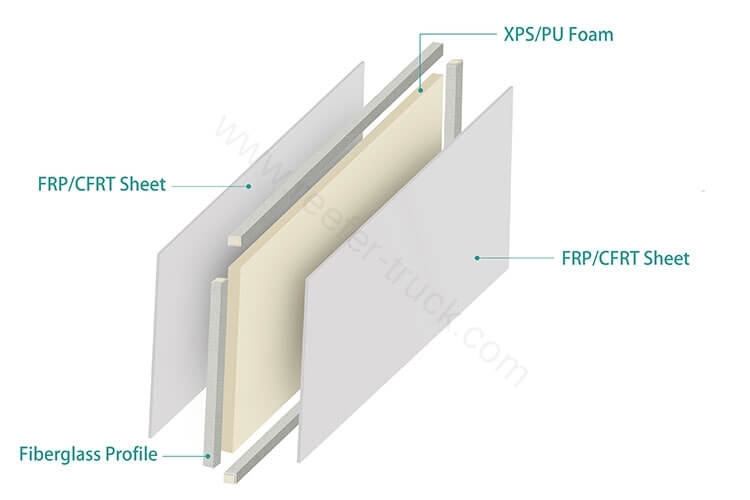

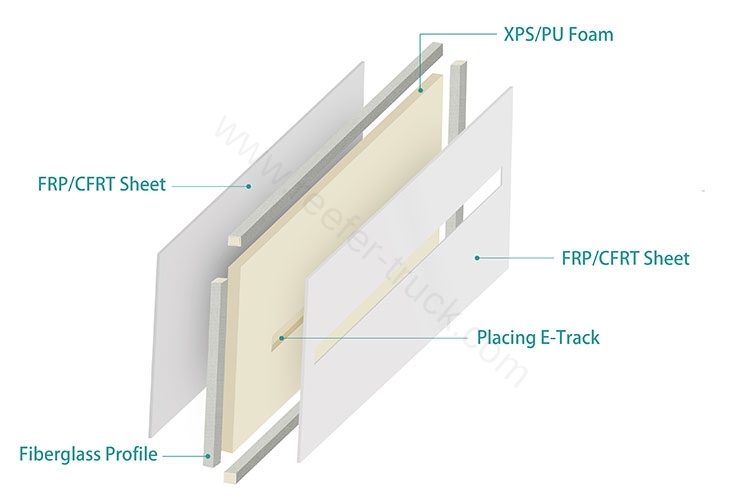

Refrigerated truck/trailer Panels construction:

Refrigerated truck roof panel: FRP XPS/PU CFRT sandwich panel

Front panel: FRP XPS/PU CFRT sandwich panel

Side Panels: FRP XPS/PU CFRT Sandwich Panel

Rear & Side Door: FRP XPS/PU CFRT Sandwich Panel

Floor: Aluminum wood panel with FRP foam core